No need to mask the conductive parts!?

DM SeriesTM is the conduct electricity anodizing, that have the effects of electromagnetic wave shielding , and prevent static electricity.

Overview of DM SeriesTM (Electrically Conductive Anodizing)

It is commonly known that aluminum has good electrical conductivity, but anodized aluminum is an insulating coating.

The reason is that anodized aluminum was developed by the Riken (the Institute of Physical and Chemical Research) as an insulating material, and then functional improvements such as hardness, corrosion resistance, and coloring were added to it, and it is now widely used in the world. Therefore, when it is necessary to conduct electricity, it is dealt with by chemical conversion treatment or partial masking treatment.

However, our company has overturned the conventional wisdom of anodizing by developing and putting into practical use “electrically conductive anodizing” for the first time in the world. “Conductive Mite” has good abrasion resistance and conductivity due to the ingenuity of the processing liquid and the addition of work processes.Therefore, it can be expected to be used in devices that require antistatic and electromagnetic shielding properties.In addition, because it has the same hardness as iron, it is scratch(dent)-resistant and has excellent abrasion resistance.

Features of DM SeriesTM

| For Aluminum Cast and Die-Cast | For Wrought Aluminum | |

|---|---|---|

| Color | Virtually any color | |

| Hardness | 300–350 HV (varies by alloy) | 350–400 HV (varies by alloy) |

| Coating Resistance | 100~10-2Ω (measured via 4-terminal method) | |

| Shielding Performance | 0.1MHz~1GHz Comparable to aluminum material (*slight variation by alloy) | |

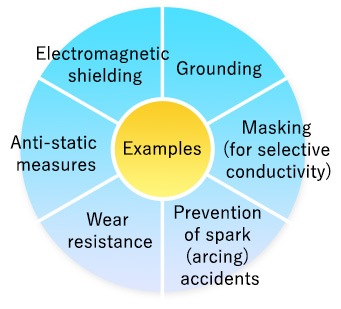

Electromagnetic Shielding Performance

Applications of DM SeriesTM

- Components requiring electrical conductivity

- Components requiring electromagnetic (EM) shielding

Materials and Sizes Compatible with DM SeriesTM

| For Aluminum Castings and Die-Casts | For Wrought Aluminum | |

|---|---|---|

| Material | Aluminum Castings: AC1A, AC2A, AC2B, AC3A, AC4A, AC4B, AC4C, AC4CH, AC4D, AC4DH, AC5A, AC7A, AC8A, AC8B, AC8C, AC9A, AC9B Aluminum Die-Casts: ADC3, ADC5, ADC6, ADC10, ADC12, ADC12Z, ADC14 | Pure Aluminum Series: A1050, A1100, A1200, etc. High tensile aluminum alloys: A2017, A2024, A7075, etc. Corrosion resisting aluminum alloys: A3003, A5052, A5056, A5083, A6061, A6063, etc. Others: A4043, AC4C |

| Size | Up to 500 × 120 × 600 mm | |

Measuring Method for DM SeriesTM

(Please read before performing any conductivity tests)

We have received many inquiries about the measurement method of the conductivity of our DM Series™, such as some users report that measuring with a tester’s probe tip sometimes indicates conductivity and sometimes does not.

Please refer to the following recommended method for conducting a continuity test.

Important Note

Due to the conductive properties of anodized aluminum, the coating must have an area or length of at least 2 mm² at the contact point.

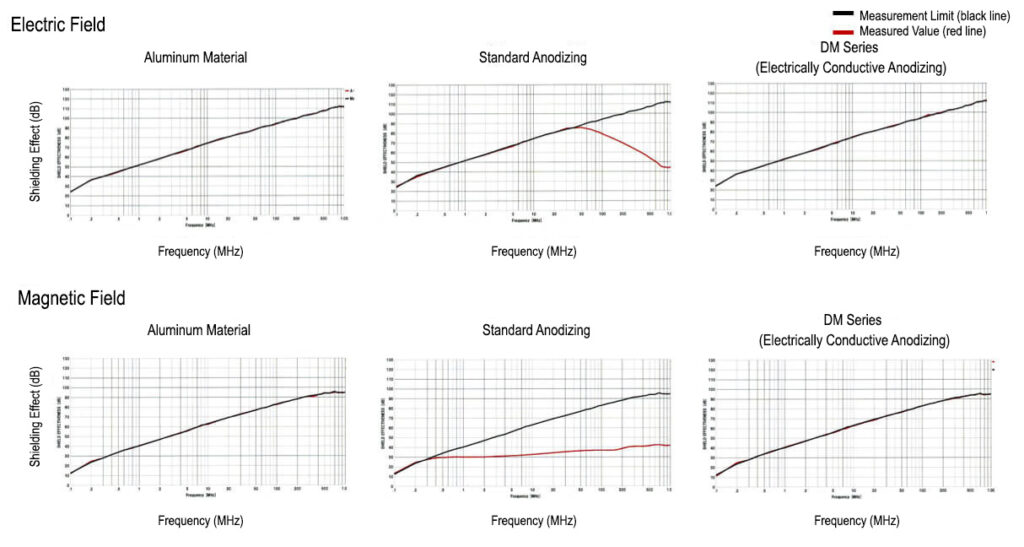

Therefore, when testing conductivity with a multimeter or tester, we recommend the following approaches:

- Hold the tester so that the measurement terminal on the DM Series side is parallel to the sample’s surface, and measure again.

- Place a piece of metal on the DM Series™ surface, then press the tester probe onto that metal.

Caution:

Using an alligator clip or another contact fixture that provides a stable contact area is highly recommended. Measuring with only the very tip of a probe may yield inconsistent results.

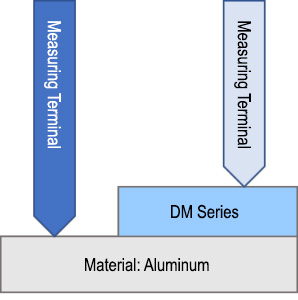

NG Example: Improper Terminal Orientation

When testing only at the very tip of the probe, you may get inconsistent readings (conductive vs. non-conductive).

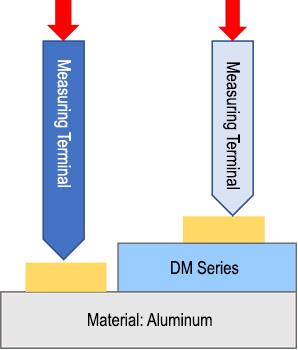

Correct Measurement Example (1): Metal + Applied Pressure

Place a piece of metal (at least 2 mm² in surface area) on top of the DM Series™ coating, then apply at least 50 g of pressure from above when measuring.

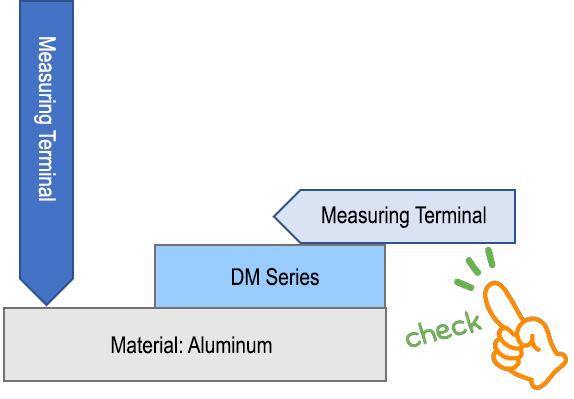

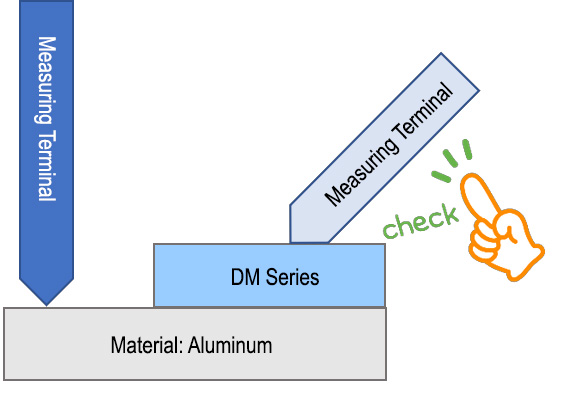

Correct Measurement Example (2): Adjust the Tester Orientation

Make the measuring terminal on the DM Series™ side parallel to the surface, or angle it to match the tip angle, and then measure.

Frequently Asked Questions

Yes. Although it depends on the aluminum alloy type, almost all color can be handled. Please consult with us for details.

A major feature of our DM SeriesTM is its electromagnetic shielding properties.

While electromagnetic shielding is said to be difficult with general anodized aluminum, DM SeriesTM has the same magnetic field shielding performance as aluminum materials, especially at frequencies from 0.1 MHz to 1 GHz.

Also, at frequencies above 1 GHz, the shielding effect is improved for both electric and magnetic fields because the material is metal.

Of cource we can.

Since conductive anodized aluminum is made from one type of anodized aluminum, it can withstand scratches caused by normal assembly work. It also has excellent corrosion resistance, so there is no problem with wiping with solvents, etc. (Note: Acidic cleaners are not recommended.)

Company Overview

Art 1 Inc.

Headquarters (Main Factory)

822-3 Shimokusayanagi, Yamato-shi, Kanagawa 242-0027, Japan

Yamato Second Factory

864-2 Shimokusayanagi, Yamato-shi, Kanagawa 242-0027, Japan

Yamato Third Factory

864-3 Shimokusayanagi, Yamato-shi, Kanagawa 242-0027, Japan